Compression spring VS independent pocket: Comprehensive analysis of mattress core technology and purchase guide

The choice of spring system directly determines whether the mattress can provide real scientific support for the spine.

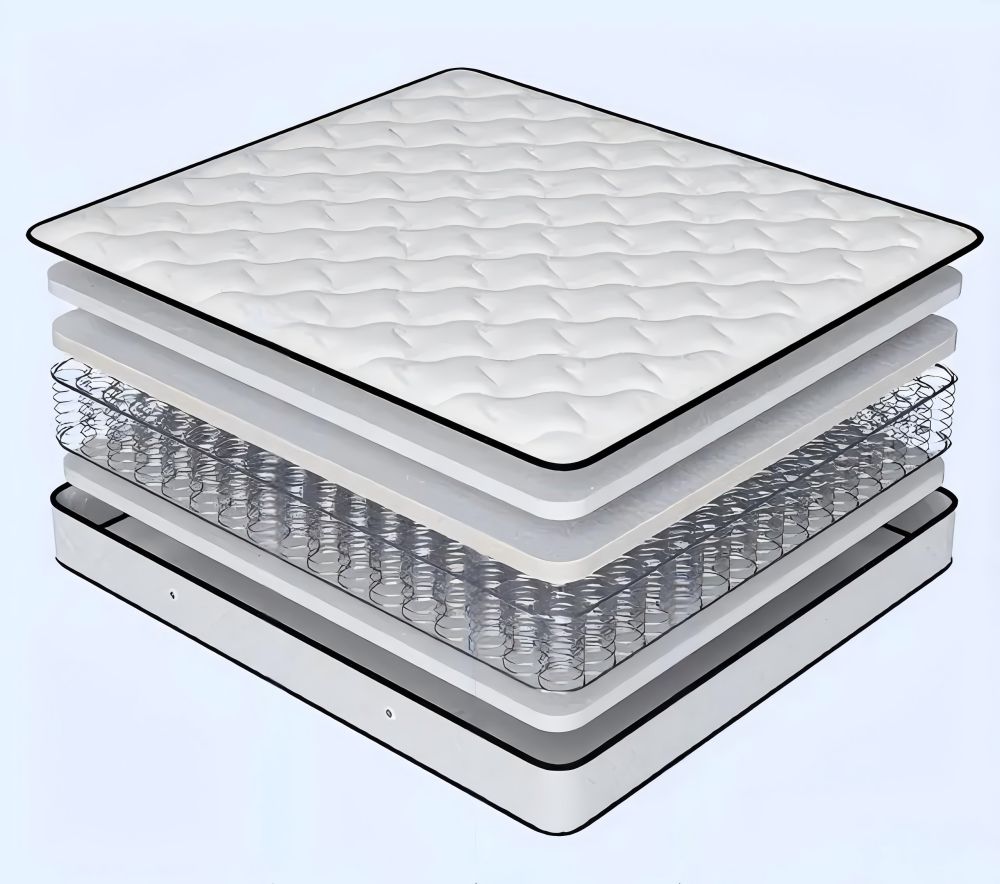

The mattress spring system has evolved over a hundred years and has developed from the traditional integral mesh spring to refined support technology represented by independent pocket springs. There are significant differences between these two core structures in mechanical properties, sleep experience and product life.

The compression spring (Bonnier system) connects all spring units in series through spiral steel wire to form a rigid overall structure; while the independent pocket technology encapsulates each spring in a non-woven bag to achieve millimeter-level precise pressure bearing and anti-interference. Understanding the difference between the two is the scientific premise for choosing an ideal mattress.

1. Structural design: from overall rigidity to independent response

Compression spring adopts a manufacturing process of continuous winding of a single steel wire, and all springs are connected in series through spiral iron wire to form a rigid mesh system (such as Bonnier spring). This integrated design makes adjacent springs highly coupled – when one place is under pressure, the stress is transmitted to the surrounding area through the metal wire mesh, resulting in the mechanical characteristics of a single hair moves the whole body.

Independent pocket springs achieve point support innovation through physical isolation:

- Each spring is individually sealed in a breathable non-woven bag, and the bags are bonded by hot melt adhesive

- A 0.5-2mm physical buffer gap is retained between the springs to completely block the vibration transmission path

- The longitudinal pocket rows are staggered to greatly improve local pressure-bearing stability

Patent data shows that the edge reinforcement technology of the pocket system (such as three-frame structure + transverse reinforcement ribs) reduces the collapse rate of the mattress by 37%, while the collapse rate of traditional compression springs is as high as 22% after three years of use due to the lack of edge support.

2. Mechanical properties: the fundamental division of support modes

The mechanical response curves of the two types of spring systems reveal their essential differences:

| Features | Compression spring | Independent pocket spring |

|---|---|---|

| Initial response sensitivity | Sluggish (needs greater pressure) | Sensitive (starts with light pressure) |

| Support curve | Steep rise | Smooth and uniform |

| Ideal load-bearing range | More than 90kg | 40-90kg |

| Anti-collapse ability | Medium (easy metal fatigue) | Excellent (partition reinforcement) |

| Edge support | Weak (no reinforcement design) | Strong (high-density frame) |

Compression spring (Bonnier system) is a non-stress structure that maintains a natural state when not under pressure. It is characterized by high initial rigidity and progressive support, especially suitable for users with large weight (>90kg). When the pressure exceeds the threshold, the overall elasticity of its spring system is significantly improved, and it is still irreplaceable in the field of extremely hard mattresses.

Independent pocket spring adopts a prestressed structure, and each spring is in a pre-compressed state when packaged. This design brings two major advantages:

- Micro-pressure response: It can react sensitively to light pressure (such as arm weight) to avoid local pressure

- Linear support curve: Provide uniform support in the ideal load-bearing range (40-90kg)

Patent tests show that pocket springs with variable wire diameter design (upper section 1.8mm/middle section 2.1mm) are 23% lighter than traditional springs, while 18% more lumbar support.

3. Anti-interference and silent performance: the invisible guardian of sleep quality

The vibration isolation performance of independent pocket springs has an overwhelming advantage:

- When the partner turns over, the vibration transmission rate is only 1/3 of the compression spring

- In the continuous turning test, the amplitude decay time of the independent pocket area is shortened to 0.8 seconds

The difference in noise control comes from the nature of the structure:

- The metal-to-metal friction of the compression spring will produce a continuous squeak (average 45dB)

- The bag system eliminates metal contact through non-woven wrapping, and the operating noise is controlled below 28dB (equivalent to whisper level)

The Journal of the American Academy of Sleep Medicine pointed out: Reducing night noise by 15dB can increase the duration of deep sleep by 23 minutes.

4. Ergonomic adaptation: from flat support to three-dimensional support

Zoned reinforcement technology shines in the independent bag system:

- Three-zone reinforcement design: The waist area uses a wire diameter of 2.3mm spring (0.4mm thicker than the head and foot area), combined with a high-density sponge lumbar support, which increases the lumbar support by 40%

- Open lumbar cavity structure: Some high-end models remove the waist covering layer and directly release the spring elastic force to avoid support loss

Compression spring improves fit through special-shaped structure:

- Dumbbell-shaped spring (large upper and lower diameters/small middle) increases the deformation space of the waist

- The edge uses a double-density spring array to delay collapse

However, human body pressure tests show that under the same weight, the independent bag system increases the contact area by 26% and reduces the peak pressure point by 19% (data source: Tempur Global Laboratory).

5. Guide to applicable scenarios: There is no best, only the most suitable

Choose compression spring (Bonnier) when you meet the following characteristics:

- Budget-sensitive: The price of the same size is 30-40% lower than the bagged system

- Prefer hard sleeping feeling: Especially suitable for elderly users or those recovering from lumbar surgery

- Heavy weight users (>90kg): The integral structure provides stronger base support

Prioritize independent bagging If you need:

- Partners sleeping in the same bed: The anti-interference system reduces sleep disturbance by 60%

- Precise support: Special physiological conditions such as pregnancy and scoliosis

- High edge utilization: Frequent sitting and lying on the bed requires enhanced support

People with a body mass index (BMI)>30 should choose independent bagging + partition reinforcement system, and ensure that the number of springs is>1200 pieces/mattress

6. Innovation Trend: Revolution of Compressible Technology

Transport volume optimization has become the focus in recent years:

- The compressible folding design locks the compressed state through the quick disassembly and assembly mechanism, reducing the transport volume by 70%

- The linked spring mattress introduces folding buffer strips (foam sponge/latex) to achieve three-stage folding

Material technology integration improves comprehensive performance:

- The composite structure of jute top pad + latex layer increases breathability while dispersing pressure

- The layered coupling system of memory foam and spring shortens the dynamic response time to 0.4 seconds

Data from the International Furniture Committee show that in 2024, compressible mattresses accounted for 58% of e-commerce channels, and the return rate was 27% lower than that of traditional mattresses (reduced transportation damage is the main factor).

Summary: Decision-making framework for scientific selection

Compressed springs (such as the Bonnier system) still have irreplaceable value in the field of hard mattresses and large body weight support due to their sturdy structure and low cost. Although the mechanical characteristics of its overall response limit the precise support performance, the basic performance can be optimized through edge reinforcement and special-shaped springs (such as dumbbell-shaped design).

Independent pocket springs represent the advanced direction of ergonomics: through partition reinforcement, variable wire diameter design and compressible structure, the sleeping experience is fully upgraded. Its advantages are particularly significant in the scenarios of sleeping with partners, precise support and e-commerce transportation.

DUK

Q1: What’s the main difference between Bonnel and pocket springs?

A: Bonnel springs are interconnected for firm support; pocket springs are individually wrapped for precise, motion-isolated comfort.

Q2: Which spring type is better for couples?

A: Pocket springs reduce motion transfer by 60%, ideal for couples.

Q3: Do Bonnel springs last longer?

A: No. Pocket springs have 37% lower sagging rate after 3 years.

Q4: Who should choose Bonnel springs?

A: Budget buyers (>30% cheaper), heavyweight users (>90kg), or those needing ultra-firm support.

Q5: Why are pocket springs better for spine health?

A: Their zoned support increases lumbar pressure relief by 40% and body contact area by 26%.

Q6: Can pocket springs support heavy weights?

A: Yes. Opt for 1200+ coils with reinforced edges (BMI>30).